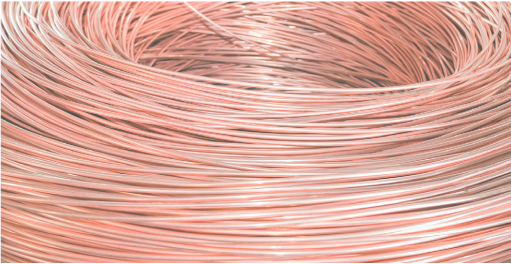

OXYGEN FREE HIGH CONDUTIVITY COPPER (OFHC)

Oxygen free high conductivity copper is produced by the direct conversion of selected refined cathodes under carefully controlled conditions to prevent any contamination of the pure oxygen-free metal during processing.

The process used to manufacture OFHC (Oxygen-Free High Conductivity) copper guarantees an exceptionally high-grade metal, boasting an impressive copper content of 99.996%. With such minimal presence of foreign elements, this copper variant brings out the inherent qualities of pure copper to a remarkable extent. These characteristics encompass remarkable ductility, exceptional electrical and thermal conductivity, substantial impact resistance, favorable creep resistance, ease of welding, and minimal volatility even under high vacuum conditions. OFHC copper contains less than 10 parts per million of oxygen within the metal, ensuring it is entirely devoid of copper oxide particles.

Lower oxygen content in oxygen free high conductivity copper has many advantages over ETP copper as shown in the following table.