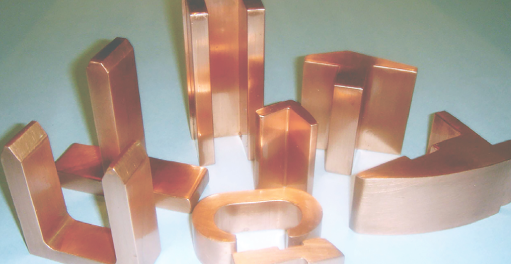

COPPER PROFILES & SECTIONS

Our advanced technology enables the availability of copper profiles in various shapes as per customers’ drawings. In electrical applications, there are many critical parts of copper profiles that need to be controlled. The extrusion process gives the benefit of wide range of sizes. Close tolerances are achieved by accurate drawing and finishing processes.

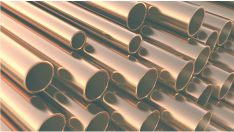

COPPER TUBES

We manufacture a diverse range of seamless tubes, available in different configurations including round, square, rectangular, hexagonal, and more. These tubes can be provided in both straight lengths and coil form for your convenience. We also manufacture fin tubes, these in comparison to plain tubes increase the surface area of the tube and improve heat transfer efficiency.

Grades- Oxygen Free High Conductivity Copper (OFE)

- Electrolytic Tough Pitch (ETP)

- Phosphorous De Oxidized (DHP)

- De Oxidized Low Phosphorous (DLP)

- Arsenic Copper